A Firm Foundation of Quality and Reliability

Since 1912, Chance® has engineered and manufactured industry-leading deep foundation solutions in Centralia, Missouri. Our helical piles and anchors have been specified for more jobs than any other helical pile brand and are still going strong.

Find a Distributor

Why Chance Foundation Solutions

As the industry pioneer of helical anchors and piles, our company is built on a deep foundation of trust and expertise.

Local foundation experts comprising the largest distribution network in North America

Engineered for dependability and long-term stability in a broad range of applications

Helical piles made with traceable prime mill-direct steel, engineered and manufactured in America

Deep Foundation Products and Tools

We design, create, and implement deep foundation systems built to fit any application. Explore our product categories to find a solution that meets your needs.

Experts in Foundation Solutions

At Chance, we offer a wealth of resources to help you navigate all your foundation projects. Dive into our library of technical literature, certifications, and educational resources to discover what makes us a leader in the foundation industry.

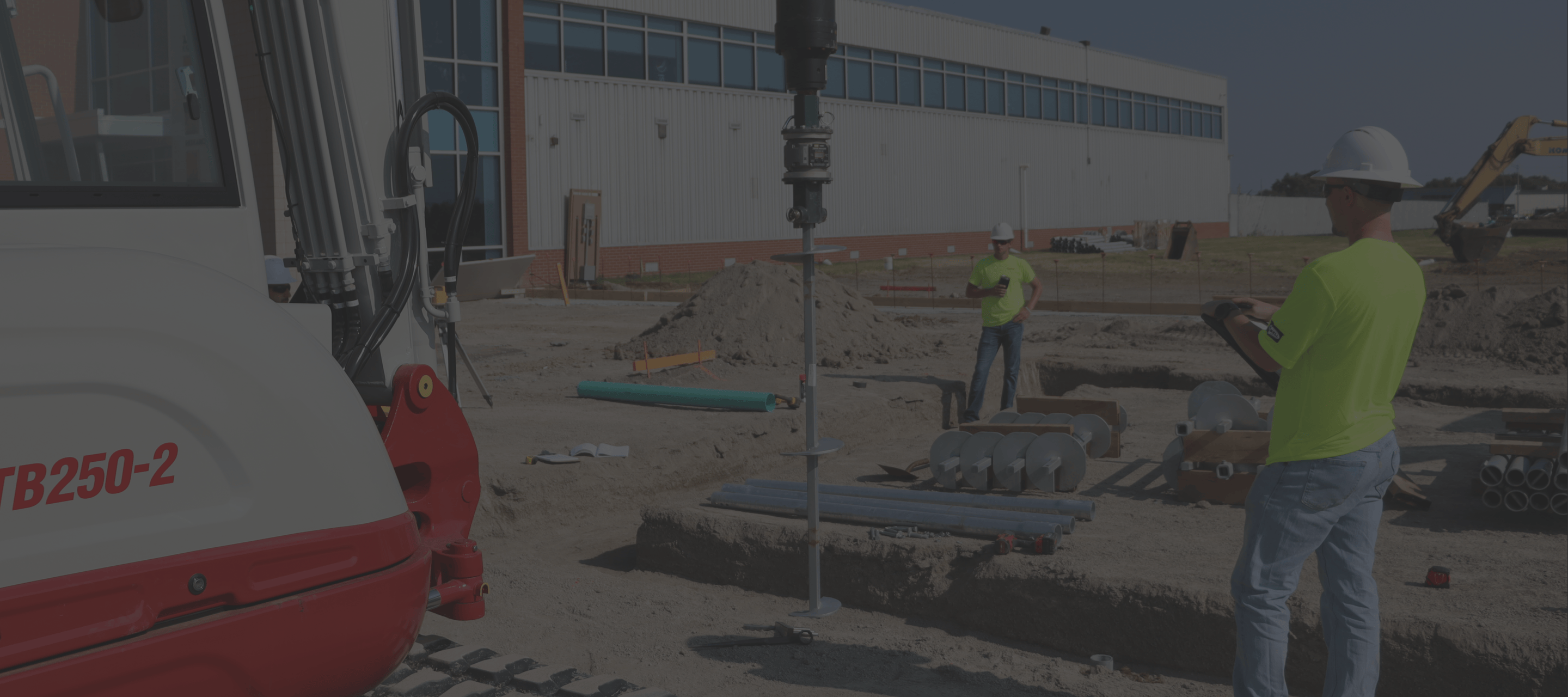

The Industry-Leading Deep Foundation Solution

When you choose Chance helical piles, you can trust they are designed by technical experts, made with high-quality materials, and backed by unrivaled customer support.

Browse all VideosVersatile Foundations for Varied Applications

From high-capacity new construction applications supporting up to 220,000 pounds per pile to limited access remediation, Chance products will ensure the long-term stability and safety of your structure.

New Construction

Enjoy faster installation, low mobilization costs, and immediate loading with a proven deep foundation for new construction projects.

Learn More

Residential

Protect your home with foundation stabilization, wall repair, or disaster recovery designed for both new construction and remediation projects.

Learn More

Oil/Gas Pipeline

Upstream, midstream, and downstream: helical piles provide strong foundations for stabilization needs for oil production, transportation, and processing.

Learn More

Solar & Wind

Site-specific solar panel and wind turbine foundations are engineered for quick installation and durability in a variety of environments.

Learn More

Earth Retention

Our helical tiebacks and Soil Screw® anchors provide necessary support for slopes, cuts, and retaining wall designs.

Learn More

Boardwalk Walkways

Our helical piles keep boardwalks secure and accessible for visitors while minimizing disturbance to the surrounding environment.

Learn More

Pole Base Foundations

A base with excellent lateral capacity for applications such as streetlights, communication infrastructure, and EV charging stations.

Learn More

Marine

Sustainable, reliable, economical: helical anchors have a wide range of proven uses for boat owners, harbormasters, and marine construction and civil engineering firms.

Learn More